Title: Understanding the Differences Between Mainstream Plug-In and Pull-Out Connector Models

Introduction:

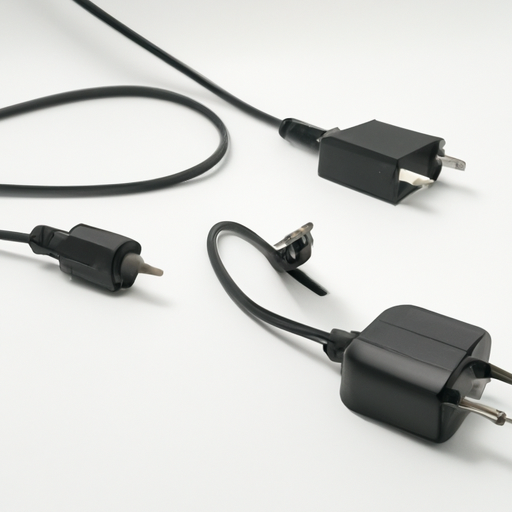

Connectors play a crucial role in various industries, facilitating the transfer of signals, power, and data between devices. Among the different types of connectors available, plug-in and pull-out connectors are widely used in mainstream applications. While both serve the same purpose of establishing a connection, they differ in terms of design, functionality, and application. In this article, we will explore the differences between these two connector models, shedding light on their unique features and use cases.

I. Plug-In Connectors:

Plug-in connectors, as the name suggests, are designed to be inserted into a corresponding receptacle to establish a connection. They are commonly used in electronic devices, appliances, and industrial equipment. Here are some key characteristics of plug-in connectors:

1. Design:

Plug-in connectors typically consist of a male connector (plug) and a female connector (receptacle). The plug features pins or blades that fit into corresponding holes or slots in the receptacle. The connectors are designed to ensure proper alignment and secure connection.

2. Ease of Use:

One of the primary advantages of plug-in connectors is their ease of use. They are designed for quick and effortless insertion, allowing users to establish connections without the need for additional tools or complex procedures.

3. Versatility:

Plug-in connectors are available in a wide range of sizes, configurations, and pin arrangements, making them versatile for various applications. They can accommodate different voltage and current requirements, enabling compatibility with diverse devices.

4. Reliability:

Plug-in connectors are known for their reliable connections. The design ensures a secure fit, minimizing the risk of accidental disconnection. Additionally, many plug-in connectors incorporate locking mechanisms or latches to enhance stability.

II. Pull-Out Connectors:

Pull-out connectors, also known as push-pull connectors, are designed to be easily disconnected by pulling or pushing a specific part of the connector. They are commonly used in applications where frequent connection and disconnection are required. Let's explore the key features of pull-out connectors:

1. Design:

Pull-out connectors feature a unique design that allows for easy disconnection. They often incorporate a locking mechanism that needs to be released before the connector can be pulled out. This design ensures a secure connection while enabling quick and effortless disconnection.

2. Quick Release:

The primary advantage of pull-out connectors is their quick-release functionality. This feature is particularly useful in applications where frequent connection and disconnection are necessary, such as medical devices, audio/video equipment, and industrial sensors.

3. Durability:

Pull-out connectors are designed to withstand repeated mating and unmating cycles. They are built with robust materials and mechanisms to ensure long-lasting performance, even in demanding environments.

4. Safety:

Pull-out connectors often incorporate safety features to prevent accidental disconnection. These may include audible or tactile feedback when the connector is fully engaged or disengaged, ensuring that the connection is secure.

III. Application Differences:

Plug-in and pull-out connectors find their applications in different industries and scenarios. Understanding their specific use cases is crucial for selecting the appropriate connector model. Here are some examples:

1. Plug-In Connectors:

- Power cords and outlets in residential and commercial buildings

- USB, HDMI, and audio connectors in consumer electronics

- Industrial connectors for machinery and equipment

- Automotive connectors for electrical systems

2. Pull-Out Connectors:

- Medical connectors for patient monitoring devices and diagnostic equipment

- Audio/video connectors for professional audio systems and broadcasting equipment

- Industrial connectors for sensors and measurement devices

- Aerospace connectors for avionics and communication systems

Conclusion:

Plug-in and pull-out connectors are two popular connector models used in mainstream applications. While plug-in connectors offer ease of use, versatility, and reliability, pull-out connectors excel in quick-release functionality, durability, and safety. Understanding the differences between these connector models is essential for selecting the right connector for specific applications. By considering factors such as the frequency of connection and disconnection, environmental conditions, and the specific requirements of the devices involved, one can make an informed decision and ensure optimal performance and reliability in their connectivity solutions.

Title: Understanding the Differences Between Mainstream Plug-In and Pull-Out Connector Models

Introduction:

Connectors play a crucial role in various industries, facilitating the transfer of signals, power, and data between devices. Among the different types of connectors available, plug-in and pull-out connectors are widely used in mainstream applications. While both serve the same purpose of establishing a connection, they differ in terms of design, functionality, and application. In this article, we will explore the differences between these two connector models, shedding light on their unique features and use cases.

I. Plug-In Connectors:

Plug-in connectors, as the name suggests, are designed to be inserted into a corresponding receptacle to establish a connection. They are commonly used in electronic devices, appliances, and industrial equipment. Here are some key characteristics of plug-in connectors:

1. Design:

Plug-in connectors typically consist of a male connector (plug) and a female connector (receptacle). The plug features pins or blades that fit into corresponding holes or slots in the receptacle. The connectors are designed to ensure proper alignment and secure connection.

2. Ease of Use:

One of the primary advantages of plug-in connectors is their ease of use. They are designed for quick and effortless insertion, allowing users to establish connections without the need for additional tools or complex procedures.

3. Versatility:

Plug-in connectors are available in a wide range of sizes, configurations, and pin arrangements, making them versatile for various applications. They can accommodate different voltage and current requirements, enabling compatibility with diverse devices.

4. Reliability:

Plug-in connectors are known for their reliable connections. The design ensures a secure fit, minimizing the risk of accidental disconnection. Additionally, many plug-in connectors incorporate locking mechanisms or latches to enhance stability.

II. Pull-Out Connectors:

Pull-out connectors, also known as push-pull connectors, are designed to be easily disconnected by pulling or pushing a specific part of the connector. They are commonly used in applications where frequent connection and disconnection are required. Let's explore the key features of pull-out connectors:

1. Design:

Pull-out connectors feature a unique design that allows for easy disconnection. They often incorporate a locking mechanism that needs to be released before the connector can be pulled out. This design ensures a secure connection while enabling quick and effortless disconnection.

2. Quick Release:

The primary advantage of pull-out connectors is their quick-release functionality. This feature is particularly useful in applications where frequent connection and disconnection are necessary, such as medical devices, audio/video equipment, and industrial sensors.

3. Durability:

Pull-out connectors are designed to withstand repeated mating and unmating cycles. They are built with robust materials and mechanisms to ensure long-lasting performance, even in demanding environments.

4. Safety:

Pull-out connectors often incorporate safety features to prevent accidental disconnection. These may include audible or tactile feedback when the connector is fully engaged or disengaged, ensuring that the connection is secure.

III. Application Differences:

Plug-in and pull-out connectors find their applications in different industries and scenarios. Understanding their specific use cases is crucial for selecting the appropriate connector model. Here are some examples:

1. Plug-In Connectors:

- Power cords and outlets in residential and commercial buildings

- USB, HDMI, and audio connectors in consumer electronics

- Industrial connectors for machinery and equipment

- Automotive connectors for electrical systems

2. Pull-Out Connectors:

- Medical connectors for patient monitoring devices and diagnostic equipment

- Audio/video connectors for professional audio systems and broadcasting equipment

- Industrial connectors for sensors and measurement devices

- Aerospace connectors for avionics and communication systems

Conclusion:

Plug-in and pull-out connectors are two popular connector models used in mainstream applications. While plug-in connectors offer ease of use, versatility, and reliability, pull-out connectors excel in quick-release functionality, durability, and safety. Understanding the differences between these connector models is essential for selecting the right connector for specific applications. By considering factors such as the frequency of connection and disconnection, environmental conditions, and the specific requirements of the devices involved, one can make an informed decision and ensure optimal performance and reliability in their connectivity solutions.