新闻中心

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change, the need for sustainable energy solutions has never been more critical. Renewable energy, derived from natural processes that are replenished constantly, offers a viable path toward reducing greenhouse gas emissions and fostering a sustainable future. This article delves into the evolution of renewable energy, exploring its historical context, various types, technological advancements, economic implications, global perspectives, and future trends. By understanding the journey of renewable energy, we can better appreciate its role in combating climate change and envision a sustainable future. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFor centuries, humanity has relied heavily on fossil fuels—coal, oil, and natural gas—as the primary sources of energy. The Industrial Revolution marked a significant turning point, as the demand for energy surged, leading to the widespread extraction and consumption of these resources. 1. **Brief History of Fossil Fuel Usage** The use of coal dates back to ancient times, but it became the dominant energy source during the 19th century. Oil emerged as a key player in the early 20th century, powering vehicles and industries. Natural gas, once considered a byproduct of oil extraction, gained prominence in the latter half of the century as a cleaner-burning alternative.2. **Environmental Consequences** The reliance on fossil fuels has had dire environmental consequences. The combustion of these fuels releases significant amounts of carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming. Additionally, fossil fuel extraction and transportation have led to habitat destruction, oil spills, and air and water pollution, posing serious threats to ecosystems and human health. B. The Emergence of Renewable EnergyIn response to the environmental challenges posed by fossil fuels, the late 20th century witnessed a renewed interest in renewable energy sources. 1. **Early Uses of Renewable Energy** Renewable energy has been harnessed for centuries, with windmills and watermills being used for grinding grain and pumping water. Solar energy was utilized in ancient civilizations for heating and cooking. However, it wasn't until the 1970s energy crisis that significant investments were made in renewable technologies.2. **Technological Advancements Leading to Modern Renewable Energy** The development of photovoltaic (PV) cells in the 1950s marked a significant milestone in solar energy technology. Wind turbine technology also advanced, leading to the construction of larger and more efficient turbines. These innovations laid the groundwork for the modern renewable energy landscape we see today. III. Types of Renewable EnergyRenewable energy encompasses a diverse range of sources, each with its unique characteristics, benefits, and challenges. A. Solar Energy1. **How Solar Panels Work** Solar panels convert sunlight into electricity through the photovoltaic effect. When sunlight strikes the solar cells, it excites electrons, generating a flow of electricity. This clean energy can be used to power homes, businesses, and even feed into the grid.2. **Benefits and Challenges of Solar Energy** Solar energy is abundant, sustainable, and produces no emissions during operation. However, challenges include the intermittent nature of sunlight, the need for energy storage solutions, and the environmental impact of manufacturing solar panels. B. Wind Energy1. **Mechanisms of Wind Turbines** Wind turbines harness the kinetic energy of wind to generate electricity. As wind flows over the blades, it causes them to spin, turning a generator that produces electricity. 2. **Advantages and Limitations of Wind Energy** Wind energy is one of the fastest-growing renewable energy sources, offering a clean and sustainable alternative to fossil fuels. However, it is subject to variability in wind patterns and can impact local wildlife and landscapes. C. Hydropower1. **Overview of Hydroelectric Power Generation** Hydropower generates electricity by harnessing the energy of flowing water, typically through dams. Water released from the reservoir spins turbines connected to generators, producing electricity.2. **Environmental Considerations and Sustainability** While hydropower is a reliable and efficient energy source, it can disrupt local ecosystems, displace communities, and alter water quality. Sustainable practices, such as run-of-the-river systems, aim to mitigate these impacts. D. Biomass and Biofuels1. **Definition and Types of Biomass** Biomass refers to organic materials, such as plant and animal waste, that can be used for energy production. Common types include wood, agricultural residues, and dedicated energy crops.2. **Role in Energy Production and Sustainability** Biomass can be converted into biofuels, such as ethanol and biodiesel, providing a renewable alternative to fossil fuels. However, concerns about land use, food security, and emissions from biomass combustion must be addressed. E. Geothermal Energy1. **Explanation of Geothermal Systems** Geothermal energy harnesses heat from the Earth's interior to generate electricity or provide direct heating. This is achieved by tapping into geothermal reservoirs, where hot water or steam is extracted.2. **Potential and Challenges of Geothermal Energy** Geothermal energy is a reliable and consistent energy source, with a small land footprint. However, it is geographically limited to regions with suitable geological conditions, and the initial investment can be high. IV. The Role of Technology in Renewable EnergyTechnological advancements have played a crucial role in the growth and efficiency of renewable energy sources. A. Innovations in Energy StorageEnergy storage technologies, such as batteries, are essential for managing the intermittent nature of renewable energy sources. Advances in lithium-ion batteries and emerging technologies like solid-state batteries are improving energy storage capacity and efficiency, enabling a more reliable energy supply. B. Smart Grid Technology and Its Impact on Energy DistributionSmart grid technology enhances the efficiency and reliability of electricity distribution. By integrating digital communication and automation, smart grids can optimize energy flow, reduce outages, and facilitate the integration of renewable energy sources into the grid. C. The Role of Artificial Intelligence and Data Analytics in Optimizing Energy UseArtificial intelligence (AI) and data analytics are transforming the energy sector by enabling predictive maintenance, demand forecasting, and energy management. These technologies help optimize energy consumption, reduce waste, and enhance the overall efficiency of renewable energy systems. V. Economic Implications of Renewable EnergyThe transition to renewable energy has significant economic implications, from job creation to cost competitiveness. A. Job Creation in the Renewable Energy SectorThe renewable energy sector has become a major source of job creation, with millions of jobs in solar, wind, and other renewable technologies. These jobs range from manufacturing and installation to maintenance and research, contributing to local economies and workforce development. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy has declined dramatically over the past decade, making it increasingly competitive with fossil fuels. Advances in technology, economies of scale, and government incentives have driven down costs, making renewable energy a viable option for consumers and businesses alike. C. Government Policies and Incentives Promoting Renewable Energy AdoptionGovernments worldwide are implementing policies and incentives to promote renewable energy adoption. These include tax credits, subsidies, and renewable portfolio standards, which encourage investment in clean energy technologies and support the transition to a low-carbon economy. VI. Global Perspectives on Renewable EnergyThe adoption of renewable energy varies significantly across countries, influenced by factors such as policy frameworks, resource availability, and technological capabilities. A. Case Studies of Countries Leading in Renewable Energy Adoption1. **Germany's Energiewende** Germany's Energiewende (energy transition) is a comprehensive policy initiative aimed at transitioning to a sustainable energy system. The country has made significant investments in solar and wind energy, achieving a substantial reduction in greenhouse gas emissions.2. **China’s Investment in Solar and Wind Energy** China has emerged as a global leader in renewable energy, investing heavily in solar and wind technologies. The country is the largest producer of solar panels and has implemented ambitious targets for renewable energy generation. B. Challenges Faced by Developing Countries in Transitioning to Renewable EnergyDeveloping countries often face unique challenges in transitioning to renewable energy, including limited access to financing, inadequate infrastructure, and reliance on fossil fuels. International support and investment are crucial to overcoming these barriers and promoting sustainable energy development. C. International Agreements and CollaborationsInternational agreements, such as the Paris Agreement, play a vital role in fostering global cooperation on climate change and renewable energy. These agreements set targets for emissions reductions and encourage countries to share knowledge and resources in the pursuit of sustainable energy solutions. VII. Future Trends in Renewable EnergyThe future of renewable energy is promising, with several trends shaping its growth and development. A. Predictions for Renewable Energy GrowthAs technology continues to advance and costs decline, renewable energy is expected to play an increasingly significant role in the global energy mix. According to the International Energy Agency (IEA), renewables could account for nearly 80% of global electricity generation by 2050. B. Emerging TechnologiesInnovative technologies, such as floating solar farms, advanced wind turbines, and energy-efficient building materials, are set to revolutionize the renewable energy landscape. These advancements will enhance energy generation, storage, and efficiency, paving the way for a more sustainable future. C. The Role of Public Awareness and EducationPublic awareness and education are critical in promoting renewable energy adoption. As individuals and communities become more informed about the benefits of renewable energy, they are more likely to support policies and initiatives that foster sustainable energy solutions. VIII. ConclusionThe evolution of renewable energy represents a vital shift toward a sustainable future. As we confront the challenges of climate change and environmental degradation, the importance of transitioning to renewable energy sources cannot be overstated. By embracing solar, wind, hydropower, biomass, and geothermal energy, we can reduce our reliance on fossil fuels, create jobs, and foster economic growth.The journey toward a sustainable future requires collective action from individuals, businesses, and governments. By investing in renewable energy technologies, supporting policies that promote clean energy, and raising awareness about the importance of sustainability, we can pave the way for a cleaner, greener planet.As we look ahead, the vision for a sustainable future powered by renewable energy is within our reach. Together, we can create a world where clean energy is the norm, and the health of our planet is prioritized for generations to come. IX. References1. International Energy Agency (IEA). (2021). World Energy Outlook 2021.2. REN21. (2021). Renewables 2021 Global Status Report.3. U.S. Department of Energy. (2020). Solar Energy Technologies Office.4. Global Wind Energy Council. (2021). Global Wind Report 2021.5. International Renewable Energy Agency (IRENA). (2021). Renewable Power Generation Costs in 2020.This comprehensive exploration of renewable energy highlights its evolution, significance, and potential for a sustainable future. By understanding the past and present, we can better navigate the path forward in our quest for a cleaner, greener world.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change, the importance of renewable energy has never been more pronounced. Renewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. The transition to renewable energy is crucial in combating climate change, reducing greenhouse gas emissions, and fostering sustainable development. This article will explore the historical context of energy sources, the various types of renewable energy, the role of technology, economic implications, global perspectives, future trends, and ultimately, the vision for a sustainable future powered by renewable energy. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their Impact 1. Brief History of Fossil Fuel UsageFossil fuels, including coal, oil, and natural gas, have been the backbone of industrial development since the 18th century. The Industrial Revolution marked a significant shift in energy consumption, with coal powering steam engines and later, oil and gas fueling transportation and electricity generation. This reliance on fossil fuels has led to unprecedented economic growth and technological advancement but has also come at a significant environmental cost. 2. Environmental ConsequencesThe extraction and combustion of fossil fuels have resulted in severe environmental degradation. Air pollution, water contamination, and habitat destruction are just a few of the consequences. Moreover, the burning of fossil fuels is the primary source of carbon dioxide emissions, a major contributor to global warming and climate change. As the effects of climate change become increasingly evident, the need for a transition to cleaner energy sources has become urgent. B. The Emergence of Renewable Energy 1. Early Uses of Renewable EnergyThe use of renewable energy is not a new concept. Ancient civilizations harnessed wind and water for sailing and milling grain. The sun has been used for heating and cooking for millennia. However, it wasn't until the late 19th and early 20th centuries that renewable energy began to gain traction as a viable alternative to fossil fuels. 2. Technological Advancements Leading to Modern Renewable EnergyThe latter half of the 20th century saw significant technological advancements in renewable energy. The development of photovoltaic cells in the 1950s marked the beginning of modern solar energy. Wind turbines became more efficient and cost-effective, while hydroelectric power plants expanded globally. These advancements laid the groundwork for the renewable energy revolution we are witnessing today. III. Types of Renewable Energy A. Solar Energy 1. How Solar Panels WorkSolar energy is harnessed through photovoltaic (PV) cells that convert sunlight directly into electricity. When sunlight hits the PV cells, it excites electrons, creating an electric current. This electricity can be used immediately or stored in batteries for later use. 2. Benefits and Challenges of Solar EnergyThe benefits of solar energy are manifold. It is abundant, sustainable, and produces no emissions during operation. However, challenges remain, including the high initial costs of installation, the need for large areas for solar farms, and the intermittent nature of sunlight. B. Wind Energy 1. Mechanism of Wind TurbinesWind energy is generated by converting the kinetic energy of wind into mechanical power through wind turbines. As wind passes over the blades, it causes them to spin, which turns a generator to produce electricity. 2. Advantages and Limitations of Wind EnergyWind energy is one of the fastest-growing renewable energy sources. It is clean, abundant, and cost-effective. However, it is also subject to variability, as wind speeds can fluctuate. Additionally, concerns about noise, aesthetics, and impacts on wildlife have been raised. C. Hydropower 1. Overview of Hydroelectric Power GenerationHydropower is generated by harnessing the energy of flowing water, typically through dams. Water released from the reservoir flows through turbines, generating electricity. 2. Environmental Considerations and SustainabilityWhile hydropower is a reliable and consistent energy source, it can have significant environmental impacts, including habitat disruption and changes to water quality. Sustainable practices, such as run-of-the-river systems, are being explored to mitigate these effects. D. Biomass and Biofuels 1. Definition and Types of Biomass EnergyBiomass energy is derived from organic materials, such as plant and animal waste. It can be converted into biofuels, such as ethanol and biodiesel, or used directly for heating and electricity generation. 2. Role in Reducing Waste and Carbon EmissionsBiomass can play a crucial role in waste management and reducing carbon emissions. By utilizing waste materials, biomass energy can help divert waste from landfills while providing a renewable energy source. E. Geothermal Energy 1. Explanation of Geothermal SystemsGeothermal energy harnesses heat from the Earth's interior. This heat can be used directly for heating or converted into electricity through geothermal power plants. 2. Potential and Challenges of Geothermal EnergyGeothermal energy is a reliable and consistent energy source, with a small land footprint. However, it is geographically limited to areas with significant geothermal activity, and the initial costs of drilling and infrastructure can be high. IV. The Role of Technology in Renewable Energy A. Innovations in Energy StorageEnergy storage technologies, such as batteries, are critical for the widespread adoption of renewable energy. They allow excess energy generated during peak production times to be stored and used when production is low, ensuring a stable energy supply. B. Smart Grid Technology and Its Impact on Energy DistributionSmart grid technology enhances the efficiency and reliability of energy distribution. It allows for real-time monitoring and management of energy flow, integrating renewable energy sources and improving grid resilience. C. The Role of Artificial Intelligence in Optimizing Energy UseArtificial intelligence (AI) is increasingly being used to optimize energy consumption and production. AI algorithms can analyze data to predict energy demand, manage resources more efficiently, and reduce waste. V. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe renewable energy sector has become a significant source of job creation. From manufacturing solar panels to installing wind turbines, the transition to renewable energy is creating millions of jobs worldwide. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy has plummeted in recent years, making it competitive with fossil fuels. In many regions, solar and wind energy are now the cheapest sources of electricity, leading to increased investment and adoption. C. Government Policies and Incentives Promoting Renewable EnergyGovernments play a crucial role in promoting renewable energy through policies and incentives. Tax credits, subsidies, and renewable energy mandates encourage investment and development in the sector. VI. Global Perspectives on Renewable Energy Adoption A. Case Studies of Countries Leading in Renewable EnergyCountries like Germany, Denmark, and China are leading the way in renewable energy adoption. Germany's Energiewende policy aims to transition to a sustainable energy system, while Denmark generates over 40% of its electricity from wind. China is the largest producer of solar panels and has invested heavily in renewable energy infrastructure. B. Challenges Faced by Developing Countries in Adopting Renewable EnergyWhile many developed countries are making strides in renewable energy, developing countries face unique challenges. Limited access to financing, lack of infrastructure, and political instability can hinder the adoption of renewable technologies. C. International Agreements and CollaborationsInternational agreements, such as the Paris Agreement, aim to unite countries in the fight against climate change. Collaborative efforts are essential for sharing technology, knowledge, and resources to promote renewable energy globally. VII. Future Trends in Renewable Energy A. Predictions for Renewable Energy GrowthThe future of renewable energy looks promising, with predictions indicating continued growth. According to the International Energy Agency (IEA), renewable energy could account for nearly 80% of global electricity generation by 2050. B. Emerging Technologies and Their Potential ImpactEmerging technologies, such as floating solar farms, advanced energy storage solutions, and next-generation wind turbines, have the potential to revolutionize the renewable energy landscape. These innovations can enhance efficiency, reduce costs, and expand the applicability of renewable energy. C. The Role of Public Awareness and Education in Promoting Renewable EnergyPublic awareness and education are critical in driving the transition to renewable energy. As individuals become more informed about the benefits of renewable energy, they are more likely to support policies and initiatives that promote sustainable practices. VIII. ConclusionThe transition to renewable energy is not just a necessity; it is an opportunity to create a sustainable future for generations to come. By embracing renewable energy sources, we can reduce our reliance on fossil fuels, mitigate climate change, and foster economic growth. It is imperative that individuals, businesses, and governments work together to promote renewable energy adoption and invest in the technologies of tomorrow. The vision for a sustainable future powered by renewable energy is within our reach, and it is up to us to make it a reality. IX. References1. International Energy Agency (IEA). (2021). World Energy Outlook 2021.2. U.S. Department of Energy. (2020). Renewable Energy: A Key to a Sustainable Future.3. Global Wind Energy Council. (2021). Global Wind Report 2021.4. International Renewable Energy Agency (IRENA). (2021). Renewable Power Generation Costs in 2020.5. United Nations Framework Convention on Climate Change (UNFCCC). (2015). Paris Agreement.This comprehensive exploration of renewable energy highlights its evolution, current state, and future potential. As we stand at a critical juncture in our energy journey, the transition to renewable energy is not just an option; it is an imperative for a sustainable future.

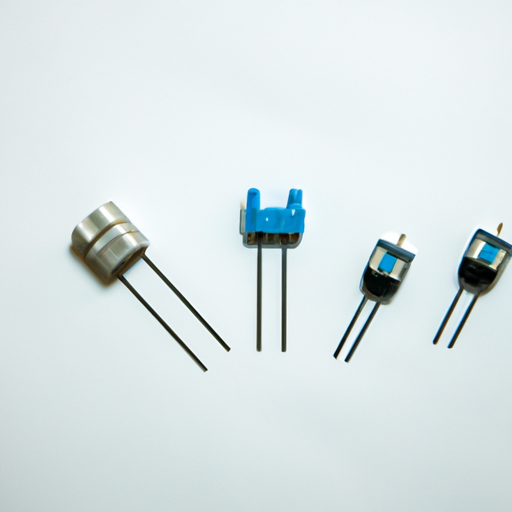

How to Choose Stock Chokes? Introduction In modern electronic devices, chokes play a crucial role as important electrical components. They can reduce electromagnetic interference, stabilize current, and protect the normal operation of circuits. With the continuous development of electronic technology, the types and applications of stock chokes in the market are becoming increasingly diverse. Therefore, choosing the right choke is particularly important. This article will delve into the basic concepts, classification, key factors in selection, performance indicators, application scenarios, and practical advice for stock chokes, helping readers make wise choices in practical applications. 1. Basic Concepts of Stock Chokes 1.1 Working Principle of Chokes Chokes are inductive components that mainly work on the principle of electromagnetic induction. When current passes through the choke, a magnetic field is generated inside the coil, which then hinders the current. This hindrance is particularly evident in alternating current, effectively suppressing high-frequency signal interference and ensuring the stability of the circuit. 1.2 Main Functions of Chokes The main functions of chokes include:Reducing electromagnetic interference: By suppressing high-frequency noise, chokes can effectively reduce electromagnetic interference and ensure the normal operation of the circuit.Stabilizing current: In situations where the current fluctuates significantly, chokes can smooth out the current changes and provide stable current output.Protecting the circuit: In cases of overload or short circuit, chokes can limit the excessive growth of current, thereby protecting circuit components from damage. 2. Classification of Stock Chokes 2.1 Classification by Material Ferrite chokes: Made of ferrite material, they have high inductance and good frequency characteristics, suitable for high-frequency applications.Air core chokes: Without a core, mainly used for low-frequency applications, with lower inductance and higher current carrying capacity. 2.2 Classification by Application General-purpose chokes: Suitable for various electronic devices, with a wide range of applications.Specialized chokes: Designed for specific applications with higher performance requirements. 2.3 Classification by Shape Round chokes: Common shape, suitable for most applications.Square chokes: Suitable for devices with limited space, better adapting to layout requirements. 3. Key Factors in Choosing Stock Chokes 3.1 Rated Current and Voltage When choosing chokes, the rated current and voltage should be considered first. The rated current refers to the maximum current that the choke can withstand under normal operating conditions, while the rated voltage refers to the maximum voltage the choke can withstand. When calculating the required values, an evaluation can be made based on the actual operating conditions of the circuit. The choice of rated values directly affects the performance and service life of the choke. 3.2 Frequency Characteristics Chokes perform differently at different frequencies. Generally, ferrite chokes perform well at high frequencies, while air core chokes have advantages at low frequencies. Therefore, when choosing chokes, the appropriate product should be selected based on the frequency range of the actual application. 3.3 Environmental Conditions Environmental conditions have a significant impact on the performance of chokes. Factors such as temperature and humidity can affect the operational status of chokes. Therefore, when choosing, the protection level of the choke should be considered to ensure its reliability in specific environments. 3.4 Size and Mounting Method The size and mounting method of chokes should also be considered. Space constraints and layout considerations will affect the choice of chokes, and the mounting method may affect their performance. Therefore, a comprehensive evaluation should be made based on the actual situation when choosing. 4. Performance Indicators of Stock Chokes 4.1 DC Resistance DC resistance is one of the important performance indicators of chokes, directly affecting current loss and heating. When choosing, chokes with lower DC resistance should be selected as much as possible to improve the efficiency of the circuit. 4.2 Inductance Inductance is the impedance of chokes to alternating current, usually proportional to frequency. When choosing, attention should be paid to the inductance value of chokes at the operating frequency to ensure they can effectively suppress electromagnetic interference. 4.3 Saturation Current Saturation current refers to the maximum current value that chokes can withstand during operation. When this value is exceeded, the performance of the chokes will significantly decrease. Therefore, when choosing, ensure that the saturation current is higher than the maximum operating current of the circuit. 4.4 Temperature Rise and Heat Dissipation Temperature rise and heat dissipation are directly related to the service life and reliability of chokes. When choosing, pay attention to the temperature rise characteristics of chokes to ensure they do not overheat during operation. 5. Common Application Scenarios 5.1 Consumer Electronics In consumer electronics products, chokes are widely used in devices such as televisions, audio systems, and mobile phones, mainly for reducing electromagnetic interference and stabilizing current. 5.2 Industrial Equipment In industrial equipment, chokes are used in motor drives, inverters, and other devices to effectively protect circuits and extend the service life of equipment. 5.3 Communication Equipment In communication equipment, chokes are used for signal processing and power management, improving signal stability and reliability. 5.4 Automotive Electronics In automotive electronics, chokes are used for power management and signal processing, effectively reducing electromagnetic interference and ensuring the normal operation of automotive electronic systems. 6. Practical Advice for Choosing Stock Chokes 6.1 Understand Specific Application Requirements Before choosing chokes, it is important to clarify specific application requirements, including current, voltage, frequency, and other parameters, to select the right product. 6.2 Refer to Industry Standards and Regulations When choosing, industry standards and regulations can be referenced to ensure that the selected product meets industry requirements. 6.3 Consult with Professionals or Suppliers During the selection process, consulting with professionals or suppliers can provide more professional advice to help make a more informed choice. 6.4 Conduct Sample Testing and Evaluation Before making the final choice, conducting sample testing and evaluation can provide a more intuitive understanding of the performance of chokes to ensure they meet actual requirements. 7. Conclusion When choosing stock chokes, it is necessary to consider factors such as rated current and voltage, frequency characteristics, environmental conditions, size, and mounting method. Understanding the basic concepts, classification, and performance indicators of chokes can help make a more informed choice. With the continuous development of electronic technology, the application scenarios of chokes are expanding, and the demand for high-performance chokes in the future market will continue to grow. It is hoped that readers can choose the right chokes according to their actual needs to ensure the stable operation of electronic devices. References - Relevant books, papers, and industry reports- Online resources and links to professional websitesThrough the above content, readers can have a comprehensive understanding of the key points in choosing stock chokes, helping to make more scientific decisions in practical applications. How to Choose Stock Chokes? Introduction In modern electronic devices, chokes play a crucial role as important electrical components. They can reduce electromagnetic interference, stabilize current, and protect the normal operation of circuits. With the continuous development of electronic technology, the types and applications of stock chokes in the market are becoming increasingly diverse. Therefore, choosing the right choke is particularly important. This article will delve into the basic concepts, classification, key factors in selection, performance indicators, application scenarios, and practical advice for stock chokes, helping readers make wise choices in practical applications. 1. Basic Concepts of Stock Chokes 1.1 Working Principle of Chokes Chokes are inductive components that mainly work on the principle of electromagnetic induction. When current passes through the choke, a magnetic field is generated inside the coil, which then hinders the current. This hindrance is particularly evident in alternating current, effectively suppressing high-frequency signal interference and ensuring the stability of the circuit. 1.2 Main Functions of Chokes The main functions of chokes include:Reducing electromagnetic interference: By suppressing high-frequency noise, chokes can effectively reduce electromagnetic interference and ensure the normal operation of the circuit.Stabilizing current: In situations where the current fluctuates significantly, chokes can smooth out the current changes and provide stable current output.Protecting the circuit: In cases of overload or short circuit, chokes can limit the excessive growth of current, thereby protecting circuit components from damage. 2. Classification of Stock Chokes 2.1 Classification by Material Ferrite chokes: Made of ferrite material, they have high inductance and good frequency characteristics, suitable for high-frequency applications.Air core chokes: Without a core, mainly used for low-frequency applications, with lower inductance and higher current carrying capacity. 2.2 Classification by Application General-purpose chokes: Suitable for various electronic devices, with a wide range of applications.Specialized chokes: Designed for specific applications with higher performance requirements. 2.3 Classification by Shape Round chokes: Common shape, suitable for most applications.Square chokes: Suitable for devices with limited space, better adapting to layout requirements. 3. Key Factors in Choosing Stock Chokes 3.1 Rated Current and Voltage When choosing chokes, the rated current and voltage should be considered first. The rated current refers to the maximum current that the choke can withstand under normal operating conditions, while the rated voltage refers to the maximum voltage the choke can withstand. When calculating the required values, an evaluation can be made based on the actual operating conditions of the circuit. The choice of rated values directly affects the performance and service life of the choke. 3.2 Frequency Characteristics Chokes perform differently at different frequencies. Generally, ferrite chokes perform well at high frequencies, while air core chokes have advantages at low frequencies. Therefore, when choosing chokes, the appropriate product should be selected based on the frequency range of the actual application. 3.3 Environmental Conditions Environmental conditions have a significant impact on the performance of chokes. Factors such as temperature and humidity can affect the operational status of chokes. Therefore, when choosing, the protection level of the choke should be considered to ensure its reliability in specific environments. 3.4 Size and Mounting Method The size and mounting method of chokes should also be considered. Space constraints and layout considerations will affect the choice of chokes, and the mounting method may affect their performance. Therefore, a comprehensive evaluation should be made based on the actual situation when choosing. 4. Performance Indicators of Stock Chokes 4.1 DC Resistance DC resistance is one of the important performance indicators of chokes, directly affecting current loss and heating. When choosing, chokes with lower DC resistance should be selected as much as possible to improve the efficiency of the circuit. 4.2 Inductance Inductance is the impedance of chokes to alternating current, usually proportional to frequency. When choosing, attention should be paid to the inductance value of chokes at the operating frequency to ensure they can effectively suppress electromagnetic interference. 4.3 Saturation Current Saturation current refers to the maximum current value that chokes can withstand during operation. When this value is exceeded, the performance of the chokes will significantly decrease. Therefore, when choosing, ensure that the saturation current is higher than the maximum operating current of the circuit. 4.4 Temperature Rise and Heat Dissipation Temperature rise and heat dissipation are directly related to the service life and reliability of chokes. When choosing, pay attention to the temperature rise characteristics of chokes to ensure they do not overheat during operation. 5. Common Application Scenarios 5.1 Consumer Electronics In consumer electronics products, chokes are widely used in devices such as televisions, audio systems, and mobile phones, mainly for reducing electromagnetic interference and stabilizing current. 5.2 Industrial Equipment In industrial equipment, chokes are used in motor drives, inverters, and other devices to effectively protect circuits and extend the service life of equipment. 5.3 Communication Equipment In communication equipment, chokes are used for signal processing and power management, improving signal stability and reliability. 5.4 Automotive Electronics In automotive electronics, chokes are used for power management and signal processing, effectively reducing electromagnetic interference and ensuring the normal operation of automotive electronic systems. 6. Practical Advice for Choosing Stock Chokes 6.1 Understand Specific Application Requirements Before choosing chokes, it is important to clarify specific application requirements, including current, voltage, frequency, and other parameters, to select the right product. 6.2 Refer to Industry Standards and Regulations When choosing, industry standards and regulations can be referenced to ensure that the selected product meets industry requirements. 6.3 Consult with Professionals or Suppliers During the selection process, consulting with professionals or suppliers can provide more professional advice to help make a more informed choice. 6.4 Conduct Sample Testing and Evaluation Before making the final choice, conducting sample testing and evaluation can provide a more intuitive understanding of the performance of chokes to ensure they meet actual requirements. 7. Conclusion When choosing stock chokes, it is necessary to consider factors such as rated current and voltage, frequency characteristics, environmental conditions, size, and mounting method. Understanding the basic concepts, classification, and performance indicators of chokes can help make a more informed choice. With the continuous development of electronic technology, the application scenarios of chokes are expanding, and the demand for high-performance chokes in the future market will continue to grow. It is hoped that readers can choose the right chokes according to their actual needs to ensure the stable operation of electronic devices. References - Relevant books, papers, and industry reports- Online resources and links to professional websitesThrough the above content, readers can have a comprehensive understanding of the key points in choosing stock chokes, helping to make more scientific decisions in practical applications.

What is the market size of coils? IntroductionCoils are essential components in electrical engineering and electronics, widely used in various devices. According to their function and structure, coils can be divided into various types, including inductor coils, transformer coils, and other types of coils. With the continuous advancement of technology, the importance of coils in modern technology is becoming increasingly prominent, especially in the fields of consumer electronics, automotive industry, industrial equipment, and medical devices. This article will delve into the market size, current status, driving factors, challenges, and future trends of the coil market. I. Current Status of the Coil Market Overview of the Global Coil MarketAccording to market research data, the global coil market has experienced significant growth in recent years. By 2023, the size of the coil market is expected to reach billions of dollars, and it is projected to continue to grow at a steady pace in the coming years. The growth of the market is mainly driven by the increasing demand for electronic products and the development of emerging technologies.In terms of market participants, the global coil market is highly competitive, with major players including some well-known electronic component manufacturers and emerging companies. These companies enhance their market competitiveness through technological innovation and product diversification. Applications of CoilsCoils have a wide range of applications, including:1. **Consumer Electronics**: Coils are used in power management, signal processing, and other functions in consumer electronics such as smartphones, tablets, and televisions. 2. **Automotive Industry**: With the rise of electric and smart vehicles, coils are increasingly used in vehicles for applications such as electric motor drive, charging systems, and sensors.3. **Industrial Equipment**: In industrial automation and control systems, coils are used for motor drive, variable frequency drives, and other control devices.4. **Medical Devices**: In medical equipment, coils are used in imaging devices, monitoring equipment, and other high-precision instruments to ensure equipment stability and reliability. II. Market Drivers Technological AdvancementsTechnological advancements are a key factor driving the growth of the coil market. The application of new materials has significantly improved the performance of coils, such as the use of high conductivity materials and high-temperature superconducting materials, making coils perform better in high-frequency and high-power applications. In addition, improvements in manufacturing processes have reduced production costs and increased production efficiency. Demand GrowthWith the proliferation of electronic products, the demand for coils has also increased. The rapid development of smartphones, wearable devices, and IoT devices has driven the demand for high-performance coils. Additionally, global attention to renewable energy has also promoted the use of coils in wind and solar power generation systems. Policy SupportGovernment support for the electronics industry has provided a favorable environment for the development of the coil market. Many countries encourage investment and innovation in the field of electronic components through tax breaks, subsidies, and research and development funding. III. Market ChallengesDespite the vast prospects of the coil market, it also faces some challenges. Fluctuations in Raw Material PricesCoil production relies on various raw materials such as copper, aluminum, and iron. Fluctuations in raw material prices may directly impact production costs, affecting the profit margins of companies. Intensified CompetitionWith the rapid development of the market, competition among domestic and foreign companies is becoming increasingly fierce. Many emerging companies enter the market with low-price strategies, putting pressure on traditional companies. Additionally, the threat of substitutes is also significant, as certain new technologies may replace the application of traditional coils. Impact of Environmental RegulationsWith global emphasis on environmental protection, many countries and regions have implemented strict environmental regulations. These regulations may increase compliance costs for companies, affecting production processes and product design. IV. Future Market Trends Market ForecastAccording to market research agencies, the coil market will continue to grow in the coming years. By 2028, the market size is expected to reach billions of dollars, with key growth regions including the Asia-Pacific, North America, and Europe. Impact of Emerging TechnologiesThe proliferation of emerging technologies will have a profound impact on the coil market. For example, the widespread adoption of 5G technology will drive the demand for high-frequency coils, while the popularity of electric vehicles will promote the demand for high-efficiency coils. The development of these technologies will bring new opportunities to the coil market. Sustainable Development and Environmental TrendsWith the growing popularity of sustainable development concepts, the coil market will also evolve towards environmental protection and sustainability. Companies will focus more on the use of green materials and the environmental friendliness of production processes to meet market and consumer demands. V. ConclusionIn conclusion, the coil market has vast potential and promising prospects. With the advancement of technology and the growth of market demand, the application areas of coils will continue to expand. For investors and companies, seizing market opportunities, focusing on technological innovation, and environmental trends will be key to future success. References- Industry reports- Academic papers- Market research dataThrough in-depth analysis of the coil market, we can see that despite facing challenges, the overall trend of the market is positive. Companies should actively respond to market changes, seize opportunities, and achieve sustainable development.

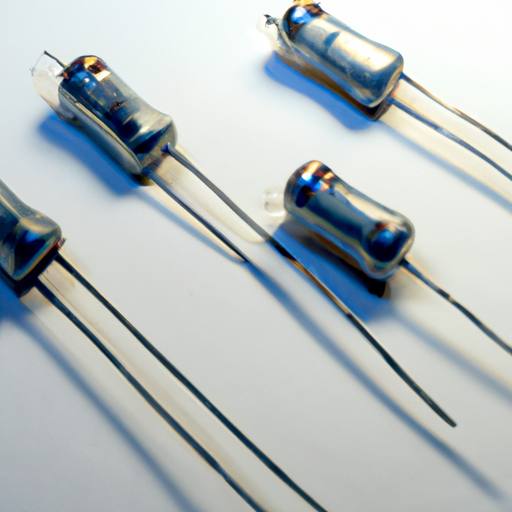

Working Principle of an Inductor IntroductionAn inductor is a passive component widely used in electronic circuits, primarily for storing energy and generating a back electromotive force when the current changes. The working principle of an inductor is closely related to electromagnetics, and understanding its basic principles is crucial for electronic and electrical engineers. This article will delve into the working principle, characteristics, and importance of inductors in practical applications. Basic Concepts of an Inductor 1. Definition of InductanceInductance refers to the phenomenon where a magnetic field is generated around a conductor when current flows through it. The magnitude of inductance is influenced by the geometry of the conductor, material, and the rate of change of current. The unit of inductance is Henry (H), where 1 Henry represents the induction electromotive force of 1 volt when the current change rate is 1 ampere per second. 2. Construction of an InductorAn inductor is typically made up of a coil wound with a wire, and there may be a magnetic core inside the coil to enhance the magnetic field. The basic construction of an inductor includes:Coil: The coil made of a conductive material (such as copper wire) is the core part of the inductor. The higher the number of turns in the coil, the greater the inductance value.Magnetic Core: The magnetic core is usually made of iron or other magnetic materials to increase the strength of the magnetic field. The material and shape of the magnetic core directly affect the performance of the inductor. 3. Types of InductorsInductors come in various types, including:Air Core Inductors: These do not have a magnetic core and are suitable for high-frequency applications due to their low losses.Iron Core Inductors: These use an iron core to increase inductance value and are suitable for low-frequency applications.Variable Inductors: These can adjust the inductance value and are commonly used in tuning circuits. Working Principle of an InductorThe working principle of an inductor is primarily based on Faraday's law of electromagnetic induction. When current flows through an inductor, the change in current generates a changing magnetic field around it. According to Faraday's law, the changing magnetic field induces an electromotive force inside the inductor, and this electromotive force's direction is opposite to the direction of the current change, known as the back electromotive force. 1. Relationship between Current Change and Magnetic FieldAccording to Faraday's law of electromagnetic induction, the induced electromotive force (E) is proportional to the rate of change of magnetic flux (dΦ/dt):\[ E = -\frac{d\Phi}{dt} \]Where Φ is the magnetic flux. The change in current leads to a change in magnetic flux, resulting in the generation of induced electromotive force. 2. Self-Inductance and Mutual InductanceSelf-Inductance: Self-inductance refers to the induced electromotive force generated by the inductor itself. The formula for self-inductance is:\[ E = -L \frac{dI}{dt} \]Where L is the inductance value, and I is the current.Mutual Inductance: Mutual inductance refers to the interaction between two inductors. When the current in one inductor changes, an induced electromotive force is generated in the other inductor. The formula for mutual inductance is:\[ E_{2} = -M \frac{dI_{1}}{dt} \]Where M is the mutual inductance coefficient. 3. Energy Storage in an InductorInductors can store energy primarily through the magnetic field they generate. The stored energy can be calculated using the following formula:\[ W = \frac{1}{2} L I^2 \]Where W is the energy, L is the inductance value, and I is the current. Inductors release the stored energy when the current changes, resulting in the continuous flow of current. Characteristics of an Inductor 1. Factors Affecting the Inductance ValueThe inductance value of an inductor is influenced by various factors, including:Number of Coil Turns: The more turns in the coil, the higher the inductance value.Magnetic Core Material: Different materials have different magnetic permeabilities, affecting the inductance value.Coil Diameter and Length: The diameter and length of the coil also affect the inductance value. 2. Q Factor and Performance of an InductorThe Q factor is an important indicator of the performance of an inductor, representing the ratio of energy loss to stored energy. The Q factor is defined as:\[ Q = \frac{X_L}{R} \]Where \( X_L \) is the reactance of the inductor, and R is the DC resistance of the inductor. Inductors with high Q values perform better in high-frequency applications and are suitable for filtering and oscillating circuits. Applications of an Inductor in CircuitsInductors have various applications in circuits, including: 1. FiltersInductors are commonly used in filters to remove unwanted high-frequency signals and smooth current fluctuations. By combining with capacitors, inductors can form low-pass, high-pass, band-pass, or band-stop filters. 2. OscillatorsIn oscillator circuits, inductors and capacitors work together to form resonant circuits. By adjusting the inductance or capacitance values, the oscillation frequency can be changed. 3. TransformersTransformers are devices composed of two or more inductors that use the principle of mutual inductance to increase or decrease voltage. Transformers are widely used in power transmission and power adapters. 4. Power ManagementIn power management circuits, inductors are used to smooth current fluctuations and improve the stability of the power supply. Inductors are commonly used in switch-mode power supplies to store and release energy. Real-World Applications of an Inductor 1. Applications of Inductors in Electronic DevicesIn modern electronic devices, inductors are widely used in power modules, RF circuits, and signal processing. For example, power management ICs in smartphones typically use inductors to improve power efficiency. 2. Applications of Inductors in Power SystemsIn power systems, inductors are used to regulate current and voltage to ensure stable power transmission. The combination of power transformers and inductors enables efficient operation of power systems. 3. Innovations in Inductors in Modern TechnologyWith technological advancements, the design and materials of inductors are continuously evolving. For example, inductors designed with new magnetic materials and miniaturized designs perform exceptionally well in high-frequency applications, meeting the demands of modern electronic devices for miniaturization and high performance. ConclusionInductors play an indispensable role in electronic circuits, and their working principle is closely related to electromagnetics. By understanding the basic concepts, working principles, and characteristics of inductors, engineers can better design and apply inductors. With the advancement of technology, the application areas of inductors will continue to expand, and there may be more innovative inductors in the future to meet the growing demands of electronic devices. References- Relevant books and papers- Online resources and websites---The above content elaborates on the working principle of an inductor and its applications in circuits, covering various aspects from basic concepts to practical applications, providing readers with a comprehensive understanding. It is hoped that this article will be helpful to you in learning and applying inductors.

What are the popular models of capacitors? IntroductionCapacitors are essential components in electronic circuits, with the basic function of storing electrical energy and releasing it when needed. The widespread use of capacitors makes them play an important role in modern electronic devices, from simple power filtering to complex signal processing, the performance of capacitors directly affects the stability and efficiency of the circuit. This article aims to introduce some popular capacitor models and their application areas, helping readers better understand the selection and use of capacitors.1. Basic classification of capacitorsCapacitors can be classified according to different standards, mainly including classification by material and by application.1.1 Classification by material1. **Ceramic capacitors**: With ceramic material as the dielectric, they have good temperature characteristics and stability, widely used in high-frequency circuits and filters.2. **Electrolytic capacitors**: Usually made of aluminum or tantalum, they have high capacitance and are suitable for power filtering and energy storage.3. **Film capacitors**: Using thin film material as the dielectric, they have low loss and high stability, commonly used in audio circuits and power circuits.4. **Aluminum electrolytic capacitors**: A common type of electrolytic capacitor, with high capacitance and low cost, widely used in various electronic devices.5. **Tantalum capacitors**: With tantalum metal as the electrode, they have high capacitance and small size, suitable for portable devices and mobile phone circuits.1.2 Classification by application1. **General capacitors**: Suitable for various common circuits, with a wide range of applications.2. **High-frequency capacitors**: Designed for high-frequency signals, suitable for RF circuits and communication equipment.3. **Filter capacitors**: Used for power filtering, removing noise and interference from the power supply.4. **High-voltage capacitors**: Designed to withstand high voltages, suitable for high-voltage circuit applications.2. Introduction of popular capacitor modelsAmong the many capacitor models, the following are some popular choices in the market.2.1 Ceramic capacitorsModel: C0G/NP0Features: C0G/NP0 capacitors have extremely low temperature drift and high stability, suitable for high-precision applications.Applications: Widely used in high-frequency circuits and filters, especially in applications requiring high stability.Model: X7RFeatures: X7R capacitors have moderate temperature drift and high capacitance, suitable for various applications.Applications: Commonly used in power decoupling and coupling circuits, effectively balancing the performance and cost of the circuit.2.2 Electrolytic capacitorsModel: OS-CONFeatures: OS-CON capacitors have low equivalent series resistance (ESR) and good high-frequency characteristics, suitable for high-frequency applications.Applications: Widely used in switch-mode power supplies and DC-DC converters, improving the efficiency and stability of power supplies.Model: Aluminum electrolytic capacitorsFeatures: Aluminum electrolytic capacitors have high capacitance and low cost, suitable for most applications.Applications: Commonly used in power filtering and energy storage, widely used in consumer electronics and industrial equipment.2.3 Film capacitorsModel: MKPFeatures: MKP capacitors have low loss and high stability, suitable for high-frequency and high-power applications.Applications: Widely used in audio circuits and power circuits, providing high-quality signal transmission.Model: MKTFeatures: MKT capacitors have moderate capacitance and good temperature characteristics, suitable for various applications.Applications: Commonly used in coupling and decoupling circuits, effectively improving the performance of the circuit.2.4 Tantalum capacitorsModel: Tantalum capacitorsFeatures: Tantalum capacitors have high capacitance and small size, suitable for applications with limited space.Applications: Widely used in portable devices and mobile phone circuits, meeting the requirements of high performance and miniaturization.3. Market trends of popular capacitor models3.1 Market demand analysisWith the rapid development of electronic products, the market demand for capacitors is also growing. Especially in the fields of electric vehicles and renewable energy, the application of capacitors is becoming more and more widespread. Electric vehicles require high-performance power management systems, while renewable energy systems require efficient energy storage solutions, all of which are driving the rapid development of the capacitor market.3.2 Technological advancementsThe application of new materials and improvements in manufacturing processes have continuously improved the performance of capacitors. For example, capacitors using new dielectric materials can operate at higher frequencies while maintaining low losses. In addition, advances in automated production technology have also increased the production efficiency and consistency of capacitors.4. Factors to consider when choosing capacitorsWhen choosing capacitors, there are several key factors to consider:4.1 CapacitanceCapacitance is one of the basic parameters of capacitors, and choosing the right capacitance is crucial for the performance of the circuit. Generally, the larger the capacitance, the more electrical energy stored, but it is also important to consider the actual requirements of the circuit to avoid overdesign.4.2 Voltage ratingVoltage rating is the maximum voltage that a capacitor can withstand, choosing the appropriate voltage rating can ensure that the capacitor does not break down during operation. It is usually recommended to choose a voltage rating slightly higher than the operating voltage of the circuit to improve safety.4.3 Temperature characteristicsTemperature has a significant impact on the performance of capacitors, especially at high temperatures, the capacitance and voltage rating of capacitors may decrease. Therefore, when choosing capacitors, it is necessary to consider the temperature range of their working environment.4.4 Size and packagingThe size and packaging of capacitors will affect the flexibility of circuit design. In applications with limited space, choosing compact capacitors is particularly important. In addition, different packaging forms will also affect the heat dissipation performance and installation method of capacitors.5. ConclusionCapacitors, as important components in electronic circuits, have a variety of models and application areas. By understanding popular capacitor models and their characteristics, designers and engineers can better choose capacitors that are suitable for their projects. In the future, with the continuous advancement of electronic technology, the capacitor market will continue to develop, and new materials and technologies will emerge, providing more possibilities for improving the performance of electronic products.References- "Capacitor Basics and Applications", Electronic Industry Press- "Modern Electronic Components", Machinery Industry Press- Relevant websites and journalsThe above is a detailed introduction to popular capacitor models and their applications, hoping to provide readers with valuable information to help them make better choices in practical applications.

Analysis of the Latest Purchasing Prices of Resistors IntroductionIn modern electronic devices, resistors play a crucial role as one of the most basic electronic components. Whether in consumer electronics, industrial equipment, or automotive electronics, resistors are widely used. With the continuous advancement of technology, the types and performance of resistors are constantly improving. When purchasing resistors, price becomes an important consideration for businesses. This article will provide an in-depth analysis of the purchasing prices of the latest resistors, discuss various factors influencing prices, and provide insights into market trends and purchasing strategies. Basic Concepts of Resistors 1. Definition and Function of ResistorsA resistor is an electronic component that restricts the flow of electric current. Its main function is to control the magnitude of current, distribute voltage, and protect other components. The working principle of resistors is based on Ohm's Law, which states that current is directly proportional to voltage and inversely proportional to resistance. 2. Types of ResistorsResistors can be classified into various types based on their characteristics and applications, including:Fixed Resistors: Their resistance value does not change with external conditions and is widely used in circuits.Variable Resistors: They can adjust the resistance value and are commonly used in applications such as volume control and dimmers.Precision Resistors: They have high accuracy and low temperature coefficient, suitable for high-demand measurement and control circuits. 3. Applications of ResistorsResistors are widely used in various fields, including but not limited to:Consumer Electronics: Such as smartphones, TVs, and audio systems.Industrial Equipment: Such as sensors, controllers, etc.Automotive Electronics: Such as engine control units, in-car entertainment systems, etc. Market Trends of the Latest Resistors 1. Technological Advancements in the Resistor MarketIn recent years, there have been continuous technological advancements in resistors. The application of new materials and processes has significantly improved the performance of resistors. For example, resistors using thin film technology have higher stability and accuracy, making them suitable for high-end electronic devices. 2. Impact of New Materials and Technologies on Resistor PerformanceThe use of new materials such as carbon nanotubes and conductive polymers is changing the design and performance of resistors. These materials not only improve the durability of resistors but also reduce production costs. 3. Influence of Environmental Regulations on Resistor ProductionWith increasingly strict environmental regulations, resistor manufacturers need to adhere to higher environmental standards. This not only affects production costs but also prompts companies to innovate in material selection and production processes. Factors Affecting Purchasing Prices 1. Raw Material CostsThe production of resistors relies on various raw materials such as carbon film, metal film, etc. Fluctuations in raw material prices directly impact the purchasing prices of resistors. For example, an increase in metal prices can lead to an increase in the cost of metal film resistors. 2. Production Processes and Technological LevelsThe complexity of production processes and technological levels also affect the prices of resistors. High-end resistors typically use more complex production processes, resulting in relatively higher prices. 3. Brand Influence and Market PositioningResistors from well-known brands are usually priced higher because they offer better quality and performance assurance. Brand positioning also influences pricing strategies. 4. Supply and Demand RelationshipThe supply and demand relationship in the market is an important factor affecting resistor prices. Prices may rise in times of high demand, while they may fall in times of oversupply. 5. Relationship between Purchase Quantity and Price DiscountsThe size of the purchase quantity also affects prices. Bulk purchases usually receive larger discounts, so companies should consider a centralized purchasing strategy. Price Range of the Latest Resistors 1. Price Comparison of Different Types of ResistorsFixed Resistors: Prices typically range from $0.01 to $0.5, depending on the resistance value and power rating.Variable Resistors: The price range is wider, generally between $0.5 and $5, depending on the adjustment range and accuracy.Precision Resistors: Due to their high accuracy and low temperature coefficient, prices usually range from $1 to $10. 2. Price Examples of Specific Brands and ModelsFor example, a well-known brand's fixed resistor (model: R1) is priced at $0.1, while its precision resistor (model: R2) is priced at $5. Prices vary significantly for different brands and models of resistors, so companies should conduct detailed comparisons when making purchases. 3. Analysis of Price FluctuationsPrice fluctuations of resistors are usually closely related to factors such as raw material costs, market demand, production capacity, etc. For example, during a global shortage of electronic components, resistor prices may significantly increase. Procurement Channels and Strategies 1. Main Procurement ChannelsWhen purchasing resistors, companies can choose from various channels, including:Electronic Component Distributors: Such as Digikey, Mouser, etc., providing a wide range of product choices and fast delivery services.Online Platforms: Such as Alibaba, Amazon, etc., suitable for small-scale purchases.Direct Purchase from Manufacturers: Suitable for bulk purchases, usually offering better prices. 2. How to Choose the Right SuppliersWhen selecting suppliers, companies should consider the following factors:Supplier's reputation and credibility: Choose suppliers with a good market reputation.Product quality and certifications: Ensure that the purchased resistors meet relevant quality standards.After-sales service: Good after-sales service can provide assurance for companies. 3. Considerations during ProcurementDuring resistor procurement, companies should pay attention to the following:Quality assurance: Ensure that the purchased resistors have quality assurance.Price transparency: Require suppliers to provide detailed price lists to avoid hidden costs. Case Studies 1. Experience Sharing of Specific Companies in Purchasing the Latest ResistorsA well-known consumer electronics company adopted a centralized purchasing strategy when purchasing the latest resistors. Through negotiations with multiple suppliers, they successfully reduced procurement costs. 2. Comparison of Successful and Failed Procurement CasesIn one procurement instance, a company failed to fully evaluate the reputation of a supplier, resulting in purchased resistors not meeting standards and causing production delays. In contrast, another company ensured product quality through strict supplier selection and successfully completed production tasks. ConclusionThrough the analysis of the purchasing prices of the latest resistors, we can see that resistor prices are influenced by various factors, including raw material costs, production processes, brand influence, etc. Companies should consider these factors comprehensively when making purchases, choose appropriate procurement channels and strategies to ensure the best purchasing prices and product quality. References- Industry Report: 2023 Global Resistor Market Analysis- Market Analysis Article: Technological Advancements and Market Trends in Resistors- Electronic Components Procurement Guide Closing WordsThe importance of resistors in the electronics industry is undeniable, and a rational procurement strategy can not only reduce costs but also improve the overall quality of products. It is hoped that the analysis in this article can provide valuable insights for companies in the procurement of resistors.

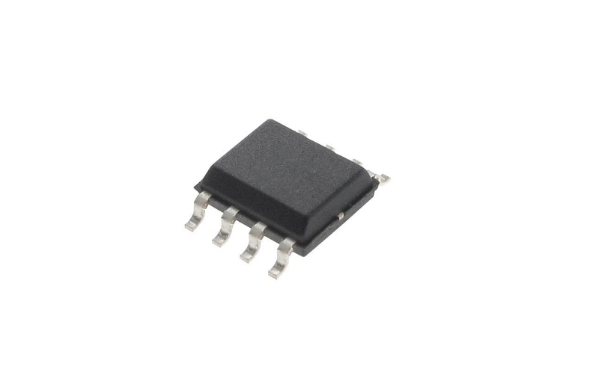

Product Features of Signal Converters IntroductionIn modern electronic devices, signal converters play a crucial role. Their main function is to convert one type of signal into another type, so that different devices can communicate and transfer data effectively. With the continuous advancement of technology, the application scope of signal converters is expanding, from home entertainment to professional fields, and to industrial applications, the demand for signal converters is increasing.This article aims to explore the main product features of signal converters, including their basic functions, design and construction features, technical specifications and performance, application scenarios, as well as market trends and future development. Through in-depth analysis of these aspects, readers will be able to better understand the importance of signal converters in modern technology and their future development potential. 2. Basic Functions of Signal Converters 1. Signal Type ConversionThe most basic function of signal converters is signal type conversion. Modern electronic devices typically use different types of signals for communication, including analog signals and digital signals. Signal converters can convert analog signals to digital signals, and vice versa. This function is crucial in many application scenarios, for example, when connecting old analog devices to modern digital devices, signal converters can ensure signal compatibility and effectiveness.Furthermore, signal converters can also convert between different interface standards. For example, HDMI, VGA, USB, and other interface standards each have their specific signal formats and transmission methods. Signal converters can facilitate communication between these interfaces, allowing users to switch between different devices freely, enhancing the flexibility of device usage. 2. Signal Enhancement and ProcessingIn addition to signal type conversion, signal converters also have the function of signal enhancement and processing. Signal amplification can effectively boost the strength of the signal, ensuring that the signal does not attenuate during long-distance transmission. This is particularly important for applications that require long-distance transmission, such as in large conference rooms or theater systems, where the strength and clarity of the signal directly impact user experience.Furthermore, signal converters also have noise suppression capabilities, effectively reducing interference during signal transmission, enhancing signal clarity. This function is particularly important in broadcasting, live streaming, and other professional fields, ensuring that the quality of the transmitted signal is optimal. 3. Product Design and Construction Features 1. Compact DesignThe design of modern signal converters tends towards miniaturization and portability. Many signal converters adopt a compact design, making it easy to fit into a backpack or pocket, allowing users to use them in different situations. This compact design not only enhances the portability of the product but also enables signal converters to adapt to different environments, whether at home, in the office, or outdoors. 2. Durability and ReliabilityDurability and reliability are also important product features of signal converters. Many high-quality signal converters use aluminum alloy casings, with good impact resistance and wear resistance, ensuring stable operation in various environments. In addition, the signal converter's anti-interference capability is also crucial, effectively resisting external electromagnetic interference, ensuring stable signal transmission. 3. User-Friendly InterfacesThe interface design of signal converters is also very important. Many signal converters use simple and user-friendly connection methods, allowing users to simply plug in the corresponding interface to complete the connection, greatly facilitating user use. At the same time, clear indicator lights and status displays allow users to understand the device's operating status in real-time, enhancing the user experience. 4. Technical Specifications and Performance 1. Supported Resolutions and Frame RatesModern signal converters typically support high-resolution and high-frame-rate transmission capabilities. For example, many signal converters can support 4K, 8K, and other high-resolution signal transmissions, meeting users' demands for high-definition image quality. In addition, high frame rate transmission capabilities can also improve the smoothness of video playback, especially in gaming and video playback scenarios, providing a better visual experience. 2. Transmission Distance and LatencyThe transmission distance and latency of signal converters are also important technical specifications. Signal transmission distance is influenced by various factors, including signal type, transmission medium, etc. Many high-quality signal converters can maintain signal stability over long distances, ensuring that users do not experience signal attenuation when using devices over a large range.Low latency design is also an important feature of signal converters. In many real-time application scenarios, such as gaming, live streaming, low latency can ensure the immediate transmission of signals, enhancing user interaction experience. 3. CompatibilityCompatibility of signal converters is also an important performance indicator. Many signal converters can be compatible with various devices, including TVs, computers, projectors, etc., meeting users' diverse needs. In addition, signal converters also need to support multiple operating systems and drivers, ensuring that users can smoothly use them on different devices. 5. Application Scenarios 1. Home EntertainmentIn the field of home entertainment, the application of signal converters is very extensive. Users can use signal converters to connect the TV with a game console to achieve a high-quality gaming experience. Furthermore, signal converters can integrate different audiovisual devices into a home theater system, enhancing the enjoyment of home viewing. 2. Professional FieldsIn professional fields, the application of signal converters is also indispensable. In conference rooms and educational environments, signal converters can integrate signals from different devices, improving the efficiency of meetings and teaching. In the broadcasting and live streaming industry, signal converters can ensure high-quality signal transmission, meeting professional requirements. 3. Industrial ApplicationsIn industrial applications, signal converters also play an important role. Signal conversion in monitoring systems can ensure the clarity and stability of monitoring images, while signal processing in automated equipment can improve production efficiency and ensure the normal operation of devices. 6. Market Trends and Future Development 1. Technological AdvancementsWith the continuous advancement of technology, emerging technologies such as 5G, Wi-Fi 6, etc., are increasingly impacting signal converters. These new technologies not only improve the speed and stability of signal transmission but also provide new possibilities for the expansion of signal converter functions. Furthermore, the trend towards intelligence and automation will also drive signal converters towards higher levels of intelligence. 2. Changing User DemandsWith the increasing demand for high-quality signals, the market for signal converters is expanding. The pursuit of portability and multifunctionality by users drives manufacturers to innovate continuously, introducing products that better meet market demands. In the future, signal converters will develop towards higher performance, stronger compatibility, and more convenient user experience. 3. Environmental Protection and SustainabilityIn terms of environmental protection and sustainability, the market for signal converters is gradually changing. More and more manufacturers are beginning to focus on the use of green materials, promoting environmentally friendly design of signal converters. Furthermore, the trend towards energy efficiency will also become an important direction for the future development of signal converters, meeting users' demands for environmentally friendly products. 7. ConclusionSignal converters play an indispensable role in modern life. They not only enable the conversion of different signals but also have multiple functions such as signal enhancement, processing, etc., widely used in home entertainment, professional fields, and industrial applications. With the continuous advancement of technology and changing user demands, the market prospects for signal converters are broad, and they will develop towards higher levels of intelligence, portability, and environmental friendliness in the future.When choosing signal converters, consumers should pay attention to the product features and performance, selecting products that meet their needs. By gaining a deeper understanding of signal converters, users can better utilize this important electronic device, enhancing efficiency in both life and work. References- Relevant technical literature and market research reports- Views and analysis from industry expertsThe above is a comprehensive discussion of the product features of signal converters, hoping to provide readers with valuable information and insights.

Adjustable inductor is a commonly used electronic component for adjusting the inductance value in a circuit. It can adjust the inductance value as needed to optimize and adjust the performance of the circuit. In electronic devices and circuits, adjustable inductors play a very important role, so there are many popular models of adjustable inductors on the market.Here are some popular models of adjustable inductors:1. ADXL362: This is a low-power three-axis accelerometer produced by ADI, with adjustable inductor function. It uses MEMS technology, with high precision and low power consumption, suitable for various mobile devices and sensor applications.2. TDK TFM201610ALMA: This is an SMD type adjustable inductor produced by TDK, with small size and high performance. It is suitable for wireless communication modules in electronic products such as mobile phones, tablets, and digital cameras.3. Murata LQW15AN: This is a chip-type adjustable inductor produced by Murata, with high quality and stability. It is suitable for matching networks and filters in various RF and microwave circuits.4. Coilcraft XAL7030: This is a high-power adjustable inductor produced by Coilcraft, with high current and low loss. It is suitable for inductance adjustment in high-power circuits such as power management and power amplifiers.5. Bourns SRN3015: This is a multi-turn adjustable inductor produced by Bourns, with high Q value and wide frequency range. It is suitable for antenna tuning and matching in RF and communication equipment.The above are some popular models of adjustable inductors, which play important roles in different application fields. With the continuous development of electronic technology, the demand for adjustable inductors is also increasing, and the future adjustable inductor market will be more prosperous.