Title: Unveiling the Advantages of FPC Flat Flexible Connector Products

Introduction (100 words)

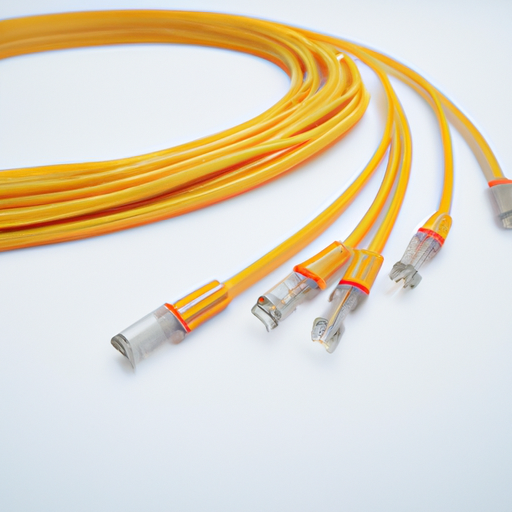

Flat Flexible Connectors (FFCs) have revolutionized the field of electronic interconnectivity, offering a flexible and reliable solution for various applications. Among the different types of FFCs, the FPC (Flexible Printed Circuit) variant stands out for its unique advantages. In this article, we will explore the numerous benefits of FPC flat flexible connector products, shedding light on their versatility, durability, cost-effectiveness, and more. By the end, readers will gain a comprehensive understanding of why FPC FFCs have become an indispensable component in modern electronic devices.

1. Flexibility and Space Efficiency (200 words)

One of the primary advantages of FPC flat flexible connector products is their exceptional flexibility. FPCs are made from thin, lightweight materials, such as polyimide, which allows them to bend and conform to various shapes and sizes. This flexibility enables FPCs to be easily integrated into tight spaces, making them ideal for compact electronic devices like smartphones, tablets, and wearables. Additionally, FPCs can be folded, twisted, or bent without compromising their electrical performance, providing designers with greater freedom in product design.

2. High Reliability and Durability (200 words)

FPC flat flexible connector products offer superior reliability and durability compared to traditional wire harnesses or ribbon cables. FPCs are manufactured using advanced techniques, such as etching or printing conductive traces onto a flexible substrate, ensuring consistent signal integrity and minimizing the risk of signal loss or interference. Moreover, FPCs are resistant to vibration, shock, and temperature variations, making them suitable for demanding environments. Their ability to withstand repeated flexing and bending without degradation further enhances their durability, reducing the need for frequent repairs or replacements.

3. Electrical Performance (200 words)

FPC flat flexible connector products exhibit excellent electrical performance, making them an ideal choice for high-speed data transmission and signal integrity. The thin and flat nature of FPCs reduces signal propagation delays, crosstalk, and electromagnetic interference, resulting in improved signal quality and reduced noise. FPCs also offer low resistance and impedance, ensuring efficient power delivery and minimizing power losses. These characteristics make FPCs suitable for applications requiring high-frequency signals, such as displays, cameras, and memory modules.

4. Cost-effectiveness (200 words)

FPC flat flexible connector products offer significant cost advantages over traditional interconnect solutions. The manufacturing process of FPCs allows for high-volume production, reducing per-unit costs. Additionally, FPCs eliminate the need for additional connectors, soldering, or wire harnesses, simplifying assembly processes and reducing labor costs. The compact size and lightweight nature of FPCs also contribute to cost savings in terms of shipping and storage. Furthermore, the durability and reliability of FPCs result in lower maintenance and repair expenses, making them a cost-effective choice in the long run.

5. Versatility and Customization (200 words)

FPC flat flexible connector products are highly versatile and can be customized to meet specific design requirements. FPCs can be manufactured in various lengths, widths, and thicknesses, allowing for precise tailoring to fit different applications. They can also be designed with specific impedance characteristics, shielding options, or even embedded components, providing enhanced functionality. FPCs can be easily integrated with other electronic components, such as connectors, switches, or sensors, further expanding their versatility. This adaptability makes FPCs suitable for a wide range of industries, including automotive, aerospace, medical, and consumer electronics.

Conclusion (100 words)

FPC flat flexible connector products offer a multitude of advantages that have made them an indispensable component in modern electronic devices. Their flexibility, reliability, electrical performance, cost-effectiveness, and versatility make them an ideal choice for various applications. As technology continues to advance, FPCs are expected to play an even more significant role in enabling innovative and compact electronic designs. With their ability to meet the demands of today's fast-paced and interconnected world, FPC flat flexible connector products are set to shape the future of electronic interconnectivity.

Title: Unveiling the Advantages of FPC Flat Flexible Connector Products

Introduction (100 words)

Flat Flexible Connectors (FFCs) have revolutionized the field of electronic interconnectivity, offering a flexible and reliable solution for various applications. Among the different types of FFCs, the FPC (Flexible Printed Circuit) variant stands out for its unique advantages. In this article, we will explore the numerous benefits of FPC flat flexible connector products, shedding light on their versatility, durability, cost-effectiveness, and more. By the end, readers will gain a comprehensive understanding of why FPC FFCs have become an indispensable component in modern electronic devices.

1. Flexibility and Space Efficiency (200 words)

One of the primary advantages of FPC flat flexible connector products is their exceptional flexibility. FPCs are made from thin, lightweight materials, such as polyimide, which allows them to bend and conform to various shapes and sizes. This flexibility enables FPCs to be easily integrated into tight spaces, making them ideal for compact electronic devices like smartphones, tablets, and wearables. Additionally, FPCs can be folded, twisted, or bent without compromising their electrical performance, providing designers with greater freedom in product design.

2. High Reliability and Durability (200 words)

FPC flat flexible connector products offer superior reliability and durability compared to traditional wire harnesses or ribbon cables. FPCs are manufactured using advanced techniques, such as etching or printing conductive traces onto a flexible substrate, ensuring consistent signal integrity and minimizing the risk of signal loss or interference. Moreover, FPCs are resistant to vibration, shock, and temperature variations, making them suitable for demanding environments. Their ability to withstand repeated flexing and bending without degradation further enhances their durability, reducing the need for frequent repairs or replacements.

3. Electrical Performance (200 words)

FPC flat flexible connector products exhibit excellent electrical performance, making them an ideal choice for high-speed data transmission and signal integrity. The thin and flat nature of FPCs reduces signal propagation delays, crosstalk, and electromagnetic interference, resulting in improved signal quality and reduced noise. FPCs also offer low resistance and impedance, ensuring efficient power delivery and minimizing power losses. These characteristics make FPCs suitable for applications requiring high-frequency signals, such as displays, cameras, and memory modules.

4. Cost-effectiveness (200 words)

FPC flat flexible connector products offer significant cost advantages over traditional interconnect solutions. The manufacturing process of FPCs allows for high-volume production, reducing per-unit costs. Additionally, FPCs eliminate the need for additional connectors, soldering, or wire harnesses, simplifying assembly processes and reducing labor costs. The compact size and lightweight nature of FPCs also contribute to cost savings in terms of shipping and storage. Furthermore, the durability and reliability of FPCs result in lower maintenance and repair expenses, making them a cost-effective choice in the long run.

5. Versatility and Customization (200 words)

FPC flat flexible connector products are highly versatile and can be customized to meet specific design requirements. FPCs can be manufactured in various lengths, widths, and thicknesses, allowing for precise tailoring to fit different applications. They can also be designed with specific impedance characteristics, shielding options, or even embedded components, providing enhanced functionality. FPCs can be easily integrated with other electronic components, such as connectors, switches, or sensors, further expanding their versatility. This adaptability makes FPCs suitable for a wide range of industries, including automotive, aerospace, medical, and consumer electronics.

Conclusion (100 words)

FPC flat flexible connector products offer a multitude of advantages that have made them an indispensable component in modern electronic devices. Their flexibility, reliability, electrical performance, cost-effectiveness, and versatility make them an ideal choice for various applications. As technology continues to advance, FPCs are expected to play an even more significant role in enabling innovative and compact electronic designs. With their ability to meet the demands of today's fast-paced and interconnected world, FPC flat flexible connector products are set to shape the future of electronic interconnectivity.