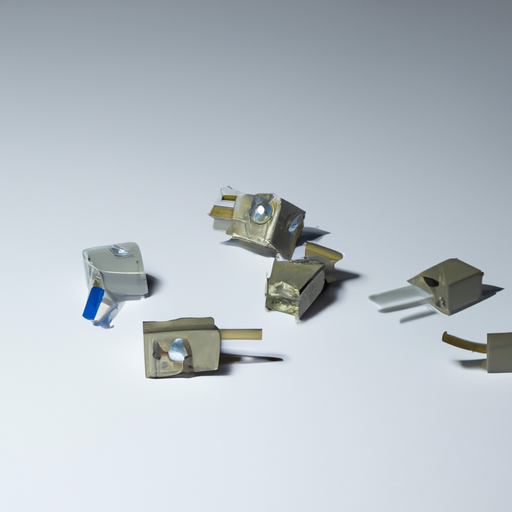

When it comes to choosing the right spot wire pins connector, there are several factors to consider in order to ensure optimal performance and reliability. These connectors are commonly used in a variety of applications, including automotive, industrial, and consumer electronics, so it is important to select the right connector for your specific needs. In this article, we will discuss some key considerations to keep in mind when choosing a spot wire pins connector.

1. Application requirements: The first step in choosing a spot wire pins connector is to determine the specific requirements of your application. Consider factors such as the number of pins needed, the current and voltage requirements, and the environmental conditions in which the connector will be used. For example, if you are working in a harsh environment with high temperatures or exposure to moisture, you will need a connector that is designed to withstand these conditions.

2. Connector type: There are several different types of spot wire pins connectors available, each with its own advantages and disadvantages. Some common types include crimp connectors, solder connectors, and insulation displacement connectors. Crimp connectors are easy to install and provide a secure connection, while solder connectors offer a more permanent connection but require soldering skills. Insulation displacement connectors are ideal for high-density applications where space is limited.

3. Pin configuration: The pin configuration of the connector is another important factor to consider. Some connectors have a straight pin configuration, while others have a right-angle or offset pin configuration. The pin configuration will depend on the layout of your circuit board and the space constraints of your application. Make sure to choose a connector with the appropriate pin configuration to ensure a proper fit.

4. Contact material: The material used for the contacts in the connector is crucial for ensuring a reliable connection. Common contact materials include brass, phosphor bronze, and gold-plated contacts. Brass contacts are cost-effective and provide good conductivity, while gold-plated contacts offer superior corrosion resistance and low contact resistance. Consider the requirements of your application when choosing the contact material for your connector.

5. Durability and reliability: It is important to choose a spot wire pins connector that is durable and reliable to ensure long-term performance. Look for connectors that are designed to withstand mechanical stress, temperature fluctuations, and environmental factors. Additionally, consider the mating cycle rating of the connector, which indicates how many times the connector can be mated and unmated before it may start to degrade.

6. Ease of installation: Finally, consider the ease of installation of the spot wire pins connector. Choose a connector that is easy to install and requires minimal tools or expertise. Look for connectors with features such as color-coded pins, polarized housings, and tool-less installation options to simplify the installation process.

In conclusion, choosing the right spot wire pins connector is essential for ensuring optimal performance and reliability in your application. By considering factors such as application requirements, connector type, pin configuration, contact material, durability, and ease of installation, you can select a connector that meets your specific needs. Take the time to research different connector options and consult with a knowledgeable supplier to find the best connector for your application.

When it comes to choosing the right spot wire pins connector, there are several factors to consider in order to ensure optimal performance and reliability. These connectors are commonly used in a variety of applications, including automotive, industrial, and consumer electronics, so it is important to select the right connector for your specific needs. In this article, we will discuss some key considerations to keep in mind when choosing a spot wire pins connector.

1. Application requirements: The first step in choosing a spot wire pins connector is to determine the specific requirements of your application. Consider factors such as the number of pins needed, the current and voltage requirements, and the environmental conditions in which the connector will be used. For example, if you are working in a harsh environment with high temperatures or exposure to moisture, you will need a connector that is designed to withstand these conditions.

2. Connector type: There are several different types of spot wire pins connectors available, each with its own advantages and disadvantages. Some common types include crimp connectors, solder connectors, and insulation displacement connectors. Crimp connectors are easy to install and provide a secure connection, while solder connectors offer a more permanent connection but require soldering skills. Insulation displacement connectors are ideal for high-density applications where space is limited.

3. Pin configuration: The pin configuration of the connector is another important factor to consider. Some connectors have a straight pin configuration, while others have a right-angle or offset pin configuration. The pin configuration will depend on the layout of your circuit board and the space constraints of your application. Make sure to choose a connector with the appropriate pin configuration to ensure a proper fit.

4. Contact material: The material used for the contacts in the connector is crucial for ensuring a reliable connection. Common contact materials include brass, phosphor bronze, and gold-plated contacts. Brass contacts are cost-effective and provide good conductivity, while gold-plated contacts offer superior corrosion resistance and low contact resistance. Consider the requirements of your application when choosing the contact material for your connector.

5. Durability and reliability: It is important to choose a spot wire pins connector that is durable and reliable to ensure long-term performance. Look for connectors that are designed to withstand mechanical stress, temperature fluctuations, and environmental factors. Additionally, consider the mating cycle rating of the connector, which indicates how many times the connector can be mated and unmated before it may start to degrade.

6. Ease of installation: Finally, consider the ease of installation of the spot wire pins connector. Choose a connector that is easy to install and requires minimal tools or expertise. Look for connectors with features such as color-coded pins, polarized housings, and tool-less installation options to simplify the installation process.

In conclusion, choosing the right spot wire pins connector is essential for ensuring optimal performance and reliability in your application. By considering factors such as application requirements, connector type, pin configuration, contact material, durability, and ease of installation, you can select a connector that meets your specific needs. Take the time to research different connector options and consult with a knowledgeable supplier to find the best connector for your application.