Wire panel connectors are essential components in various electrical and electronic systems, providing a reliable and secure connection between wires and panels. These connectors consist of several components and modules that work together to ensure a stable and efficient connection. In this article, we will explore the different components and modules that make up a wire panel connector and discuss their functions in detail.

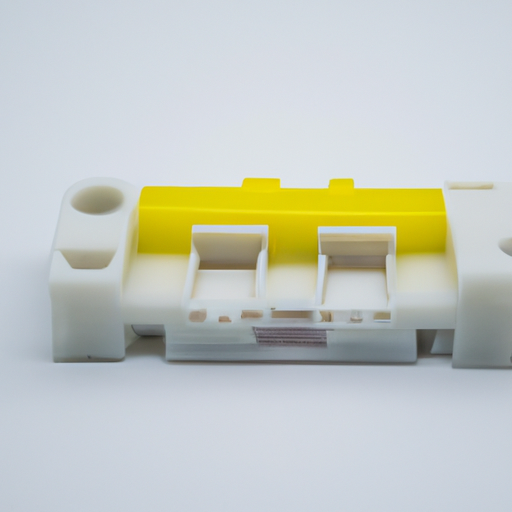

1. Housing: The housing is the outer shell of the wire panel connector, providing protection and support for the internal components. It is typically made of durable materials such as plastic or metal to withstand environmental conditions and mechanical stress. The housing also serves as a barrier to prevent dust, moisture, and other contaminants from entering the connector and causing damage to the wires.

2. Contacts: Contacts are the metal components inside the wire panel connector that establish an electrical connection between the wires. They come in various shapes and sizes, depending on the type of connector and the number of wires to be connected. Contacts are typically made of materials such as copper or brass, which offer good conductivity and corrosion resistance. The contacts are designed to securely hold the wires in place and ensure a stable electrical connection.

3. Insulation: Insulation is a crucial component of wire panel connectors that prevents electrical short circuits and ensures the safety of the system. Insulation materials such as plastic or rubber are used to cover the contacts and wires, providing a barrier against electrical current and preventing contact with other conductive materials. Proper insulation also helps to maintain the integrity of the electrical signal and prevent signal loss or interference.

4. Strain relief: Strain relief is a module in wire panel connectors that helps to protect the wires from mechanical stress and prevent them from being pulled out of the connector. It is typically a flexible material such as rubber or plastic that is attached to the housing and provides support for the wires. Strain relief modules are designed to absorb the tension and bending forces that can occur during installation or operation, ensuring that the wires remain securely connected to the contacts.

5. Locking mechanism: The locking mechanism is a feature in wire panel connectors that secures the connection between the wires and prevents accidental disconnection. It typically consists of a latch or locking tab that holds the connector in place once the wires are inserted. The locking mechanism ensures that the wires remain securely connected, even in high-vibration or high-impact environments.

6. Shielding: Shielding is a module in wire panel connectors that provides protection against electromagnetic interference (EMI) and radio frequency interference (RFI). It is typically a conductive material such as metal foil or braided wire that surrounds the wires and contacts, creating a shielded enclosure that blocks external interference. Shielding helps to maintain the integrity of the electrical signal and prevent signal degradation or distortion.

7. Sealing: Sealing is a module in wire panel connectors that provides protection against moisture, dust, and other environmental contaminants. It is typically a gasket or O-ring that is placed between the housing and the contacts to create a watertight seal. Sealing modules are essential for outdoor or harsh environment applications where the connector may be exposed to water, dirt, or other contaminants.

In conclusion, wire panel connectors are essential components in electrical and electronic systems, providing a reliable and secure connection between wires and panels. These connectors consist of various components and modules that work together to ensure a stable and efficient connection. By understanding the functions of each component and module, engineers and designers can select the right wire panel connector for their specific application and ensure the reliability and performance of their systems.

Wire panel connectors are essential components in various electrical and electronic systems, providing a reliable and secure connection between wires and panels. These connectors consist of several components and modules that work together to ensure a stable and efficient connection. In this article, we will explore the different components and modules that make up a wire panel connector and discuss their functions in detail.

1. Housing: The housing is the outer shell of the wire panel connector, providing protection and support for the internal components. It is typically made of durable materials such as plastic or metal to withstand environmental conditions and mechanical stress. The housing also serves as a barrier to prevent dust, moisture, and other contaminants from entering the connector and causing damage to the wires.

2. Contacts: Contacts are the metal components inside the wire panel connector that establish an electrical connection between the wires. They come in various shapes and sizes, depending on the type of connector and the number of wires to be connected. Contacts are typically made of materials such as copper or brass, which offer good conductivity and corrosion resistance. The contacts are designed to securely hold the wires in place and ensure a stable electrical connection.

3. Insulation: Insulation is a crucial component of wire panel connectors that prevents electrical short circuits and ensures the safety of the system. Insulation materials such as plastic or rubber are used to cover the contacts and wires, providing a barrier against electrical current and preventing contact with other conductive materials. Proper insulation also helps to maintain the integrity of the electrical signal and prevent signal loss or interference.

4. Strain relief: Strain relief is a module in wire panel connectors that helps to protect the wires from mechanical stress and prevent them from being pulled out of the connector. It is typically a flexible material such as rubber or plastic that is attached to the housing and provides support for the wires. Strain relief modules are designed to absorb the tension and bending forces that can occur during installation or operation, ensuring that the wires remain securely connected to the contacts.

5. Locking mechanism: The locking mechanism is a feature in wire panel connectors that secures the connection between the wires and prevents accidental disconnection. It typically consists of a latch or locking tab that holds the connector in place once the wires are inserted. The locking mechanism ensures that the wires remain securely connected, even in high-vibration or high-impact environments.

6. Shielding: Shielding is a module in wire panel connectors that provides protection against electromagnetic interference (EMI) and radio frequency interference (RFI). It is typically a conductive material such as metal foil or braided wire that surrounds the wires and contacts, creating a shielded enclosure that blocks external interference. Shielding helps to maintain the integrity of the electrical signal and prevent signal degradation or distortion.

7. Sealing: Sealing is a module in wire panel connectors that provides protection against moisture, dust, and other environmental contaminants. It is typically a gasket or O-ring that is placed between the housing and the contacts to create a watertight seal. Sealing modules are essential for outdoor or harsh environment applications where the connector may be exposed to water, dirt, or other contaminants.

In conclusion, wire panel connectors are essential components in electrical and electronic systems, providing a reliable and secure connection between wires and panels. These connectors consist of various components and modules that work together to ensure a stable and efficient connection. By understanding the functions of each component and module, engineers and designers can select the right wire panel connector for their specific application and ensure the reliability and performance of their systems.